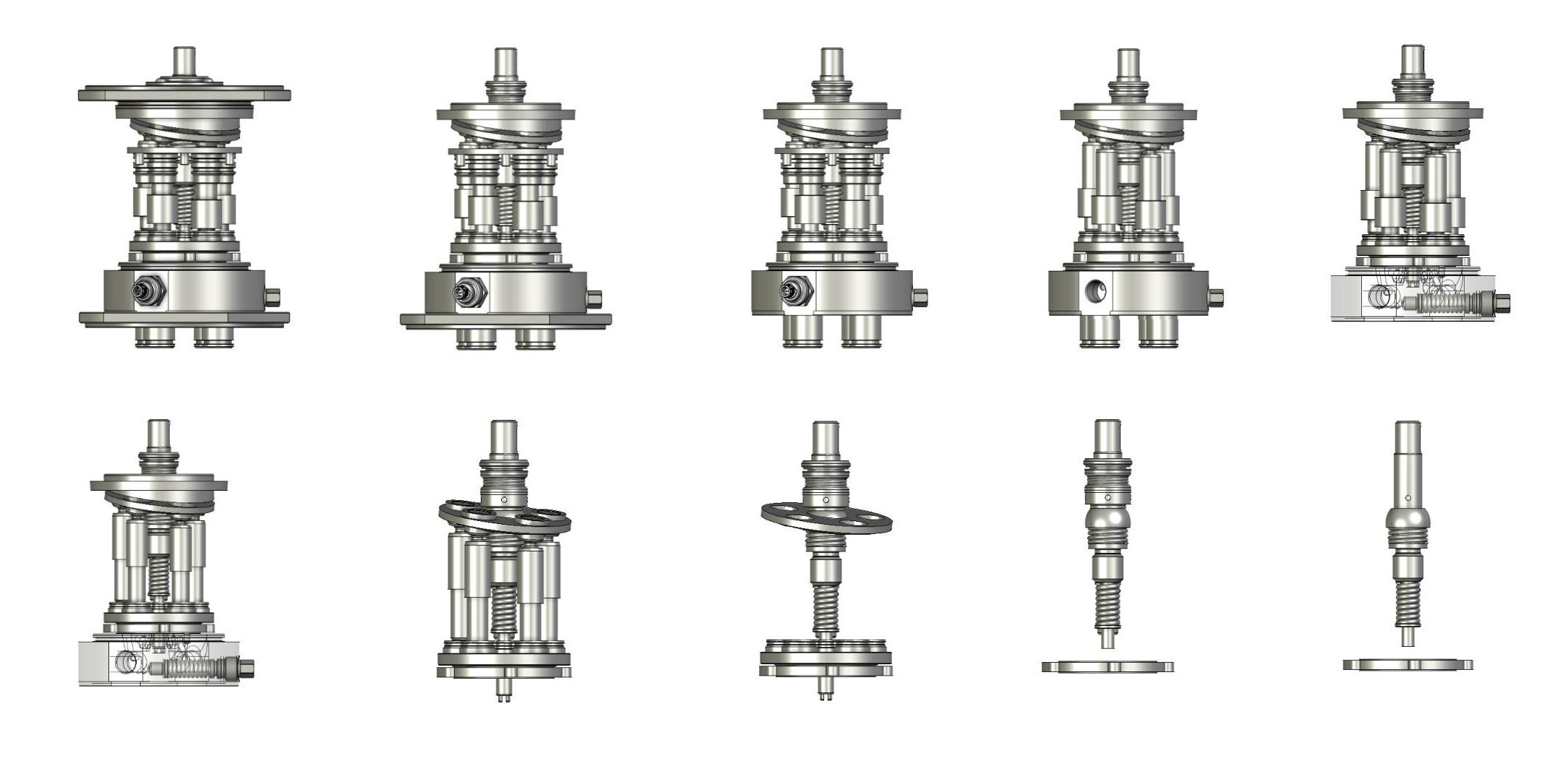

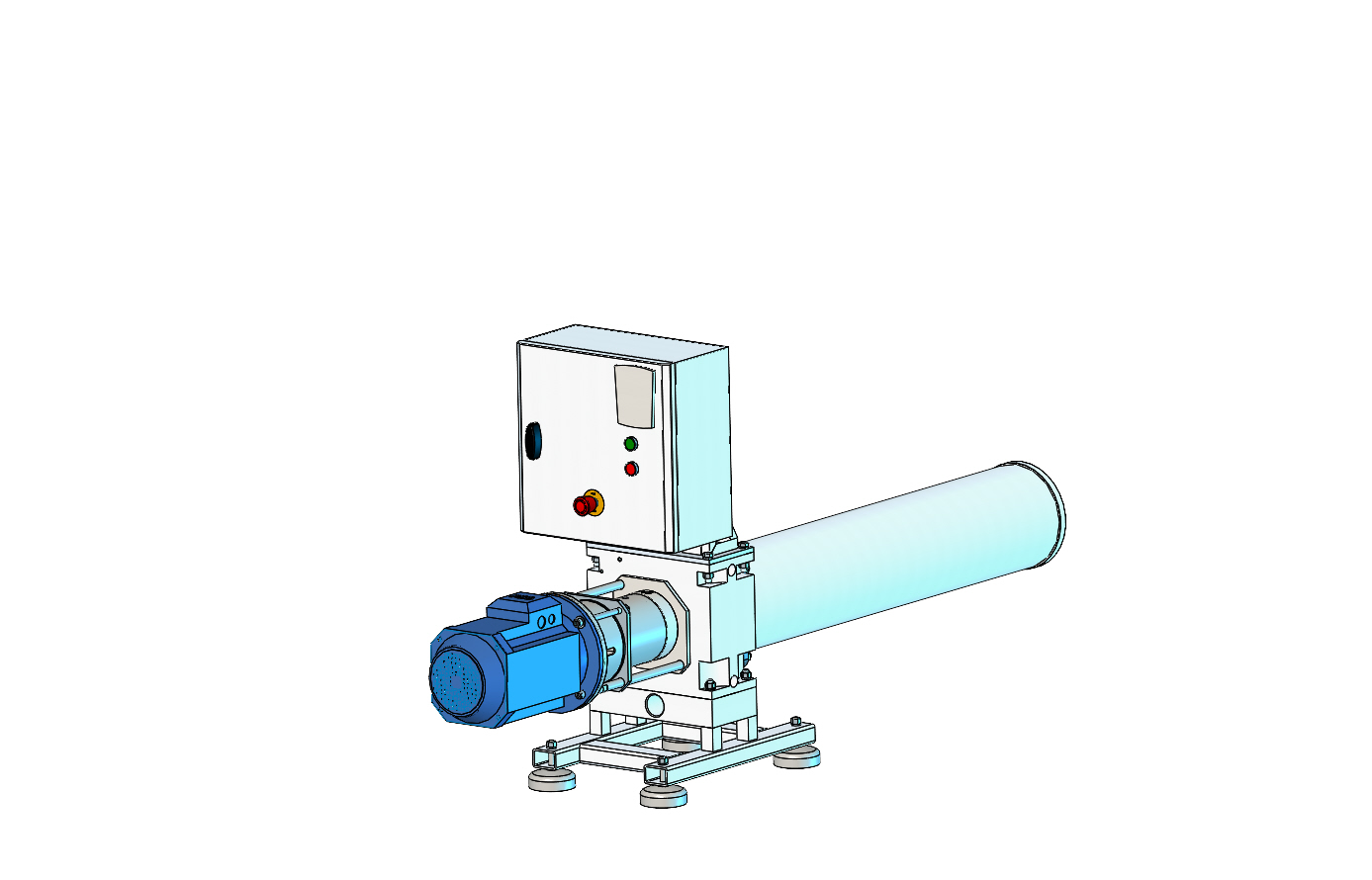

APPR high-pressure pumps were designed by Aqua-Life partnership company. APPR pumps can be used for sea or brackish water and are designed for applying in reverse osmosis systems. APPR pumps are the most advanced pumps in the world that contain an internal energy recovery device (2-in-1).

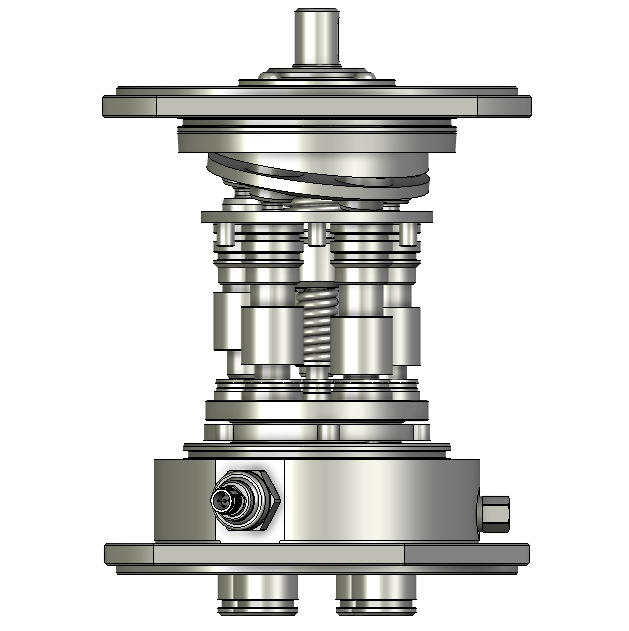

Thanks to the internal energy recovery device more than 60% of the driven energy comes from the high-pressure brine that passes through the pump and transfers energy to the plungers.

Benefits

The first pump with an integrated ERD. Most manufacturers recommend using separate energy recovery devices in order to reduce energy consumption. But in that case, the price grows up sufficiently and a new device demands space and additional fittings

Low operation cost. The pump provides uninterrupted operation without direct maintenance for at least 8000 hours

Ultra-low energy consumption. Thanks to ERD energy consumption are reduced more than two times if compared with equivalent high-pressure piston pumps

Absence of lubricants. All contacting surfaces are lubricated by the seawater flowing through them

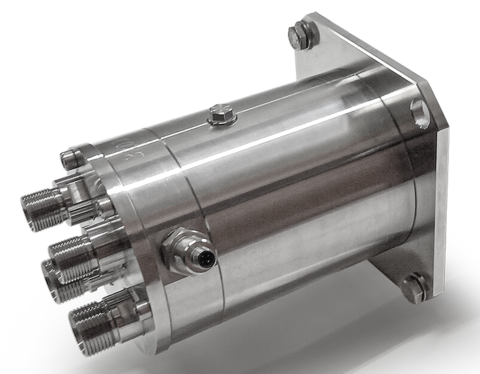

High corrosion resistance. All metal parts are made of Duplex and Super Duplex steel that has extreme resistance to corrosion. Non-metallic parts are made of PEEK polymer, which is also highly corrosion-resistant and wear-resistant

Compact size and quick installation. All APPR pumps are very compact design relatively to their flow rates and are connected directly to the motor using a coupling